E-FMD1J-D30-4P

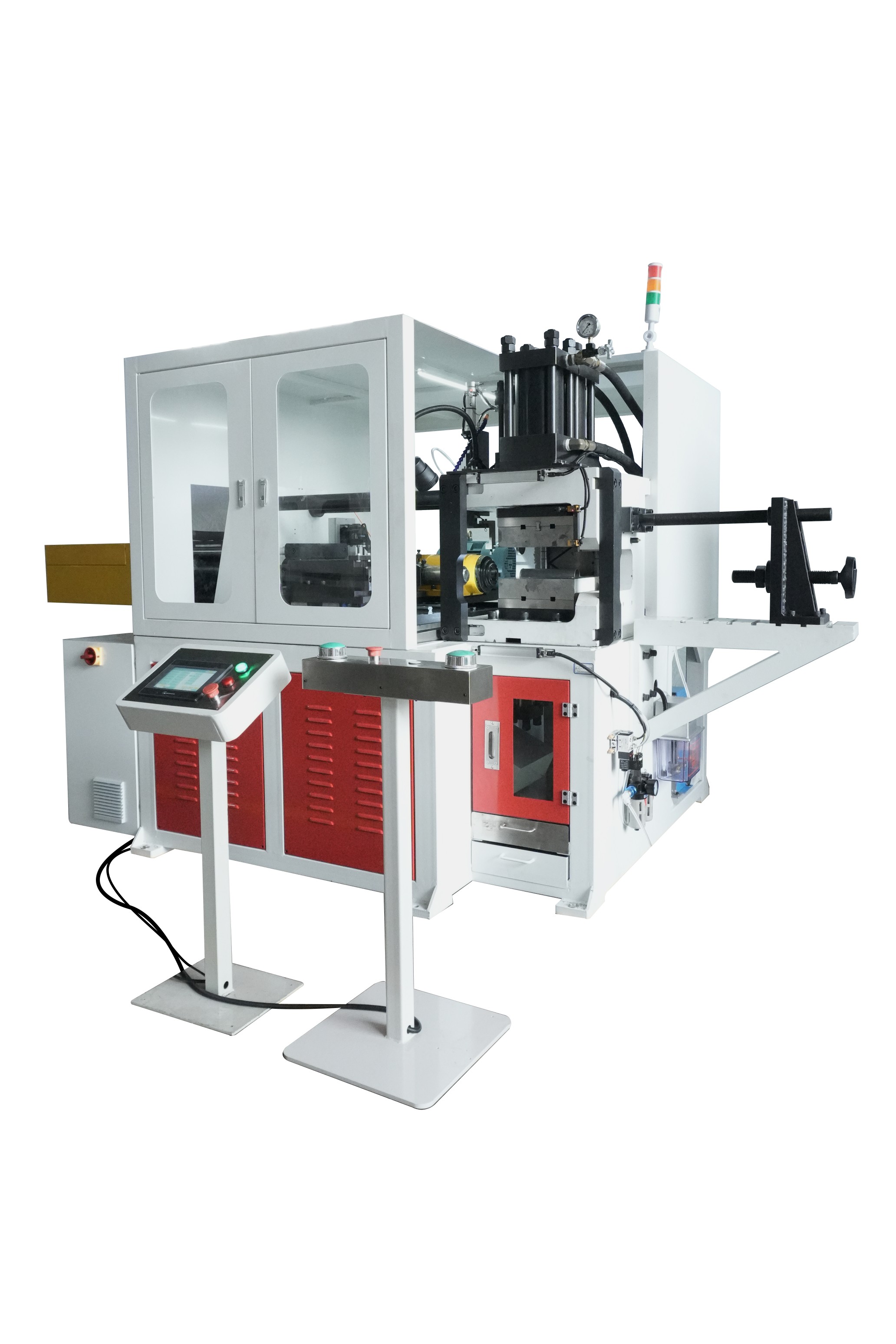

This equipment is an automated device specifically designed for the single-step clamping of pipe fittings, enabling the completion of multiple operations, including tailings removal, chamfering, and end forming.

This equipment is an automated device specifically designed for the single-step clamping of pipe fittings, enabling the completion of multiple operations, including tailings removal, chamfering, and end forming.

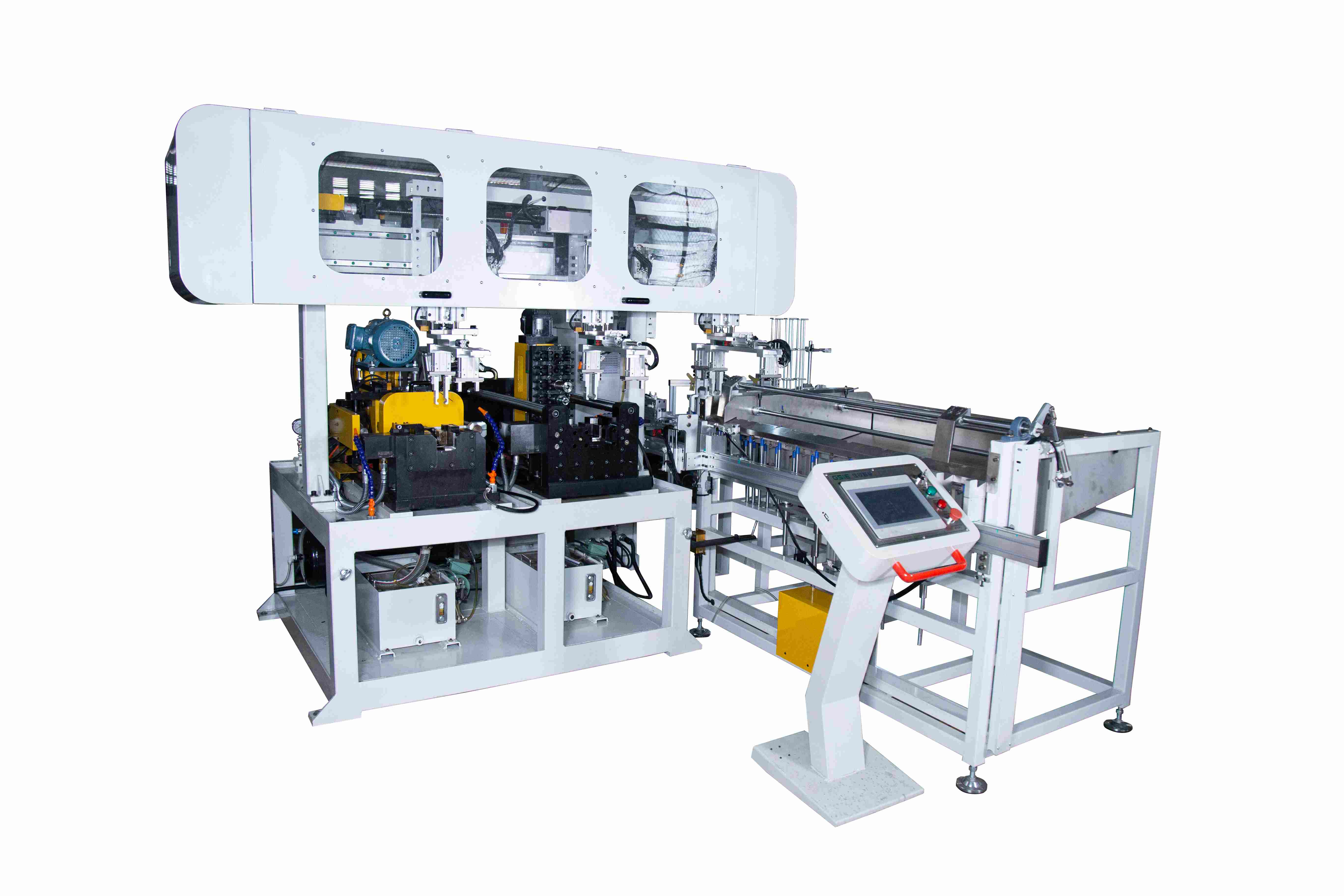

This machine is a specialized equipment for cutting chamfering and end-forming of pipes with one time clamping .

The positioning of processing station uses a servo motor-driven ball screw

transmission to esure the precision, with a

single-operation for full-cycle completion, thus enhancing production efficiency. an ideal solution for pipe end forming.

Efficient design with 5 ram station.

Double clamp die to guarantee a good-quality forming.

Meet the complex requirements of tube end forming.

Integrated with automatic feeding and unloading system to achieve highly automatic production.

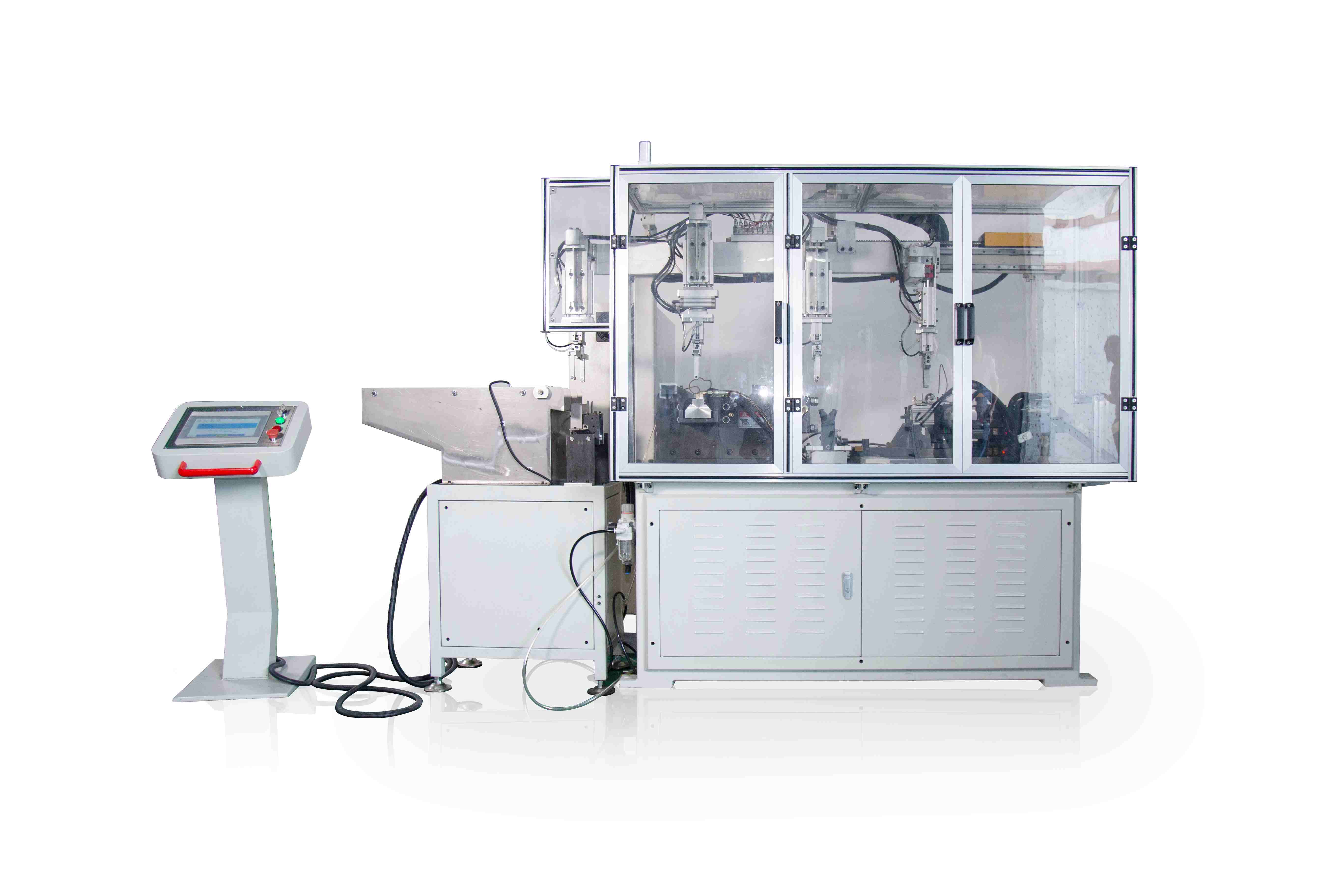

This equipment features double clamping dies and four-station forming, enabling the pipe fittings to be formed by strong extrusion at four stations.

The servo chamfering station enables complex pipe end forming and the connection of various coaxial pipe fittings.

Grooving machine is a special equipmentfor processing automobile air conditioning pipeline grooves. The clamping is driven by hydraulic pressure, the feed spinning is driven by servo motor, and the rotary groove mechanism uses a servo motor to control the collet and drive the roller to rotate and extruder the pipe. The product processed by this machine has the characteristics of high concentricity, stable performance and convenient adjustment. It is the ideal equipmentfor processing pipe grooves.

GSIE end forming series integrates multiple forming stations, which can produce the end forming products with complex process in onetime.

The machine integrates end forming and grooving All-in-one. All stations are processing simultaneously and fully automated.

The equipment integrates tube end forming, bending, auto loading and unloading.Suitable for auto tube end forming and bending of aluminum pipe elbow.

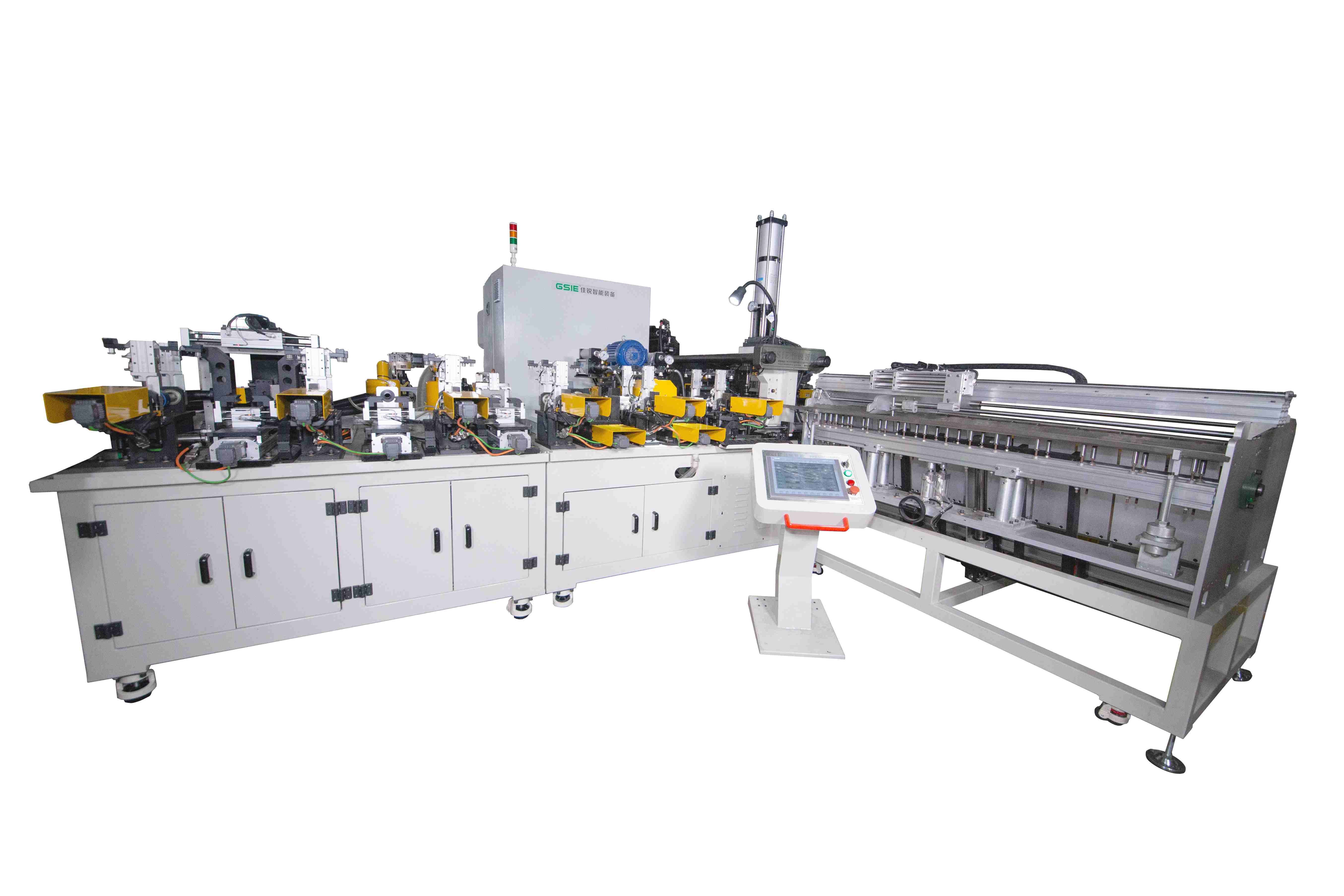

This machine is an automatic production equipment for pipe end forming, new designed for automobile safety airbag pipeline . the equipment is composed of automatic loading and unloading machine, five station end forming mechanism and detection mechanism. When start to work,firstly the operator put the workpiece into the hopper of feeding machine, then the clamping die will move to next clamping die with workpiece for next process . Each mechanism is processed simultaneously . after processing, the feeding manipulator will send the workpiece to the next process for processing, the equipment can realize the pipe fitting into the hopper after each process mechanism processing at the same time, so as to save manpower, improve efficiency. It is the ideal equipment for pipe end forming. High degree of automation, reduce labor and automatic production.

The equipment integrates auto loading and unloading, cold forming, rolling, chamfering, cleaning, inspection, riveting flange, riveting shell and other functions. The equipment is all driven by servo, modular design can be customized according to the production needs of the required functional modules. Widely used in automotive air conditioning pipeline processing and production.

Accurate positioning and quick die change.

One operation can complete one cycle of action.

The equipment integrates 5 stamping stations and an additional chamfering station, which is mainly used for cold stamping of the end of copper, aluminum and steel pipe. The equipment can be integrated with automatic loading and unloading system, which can achieve a highly automatic production.

Two tubes can be formed ata time.5 ram station.