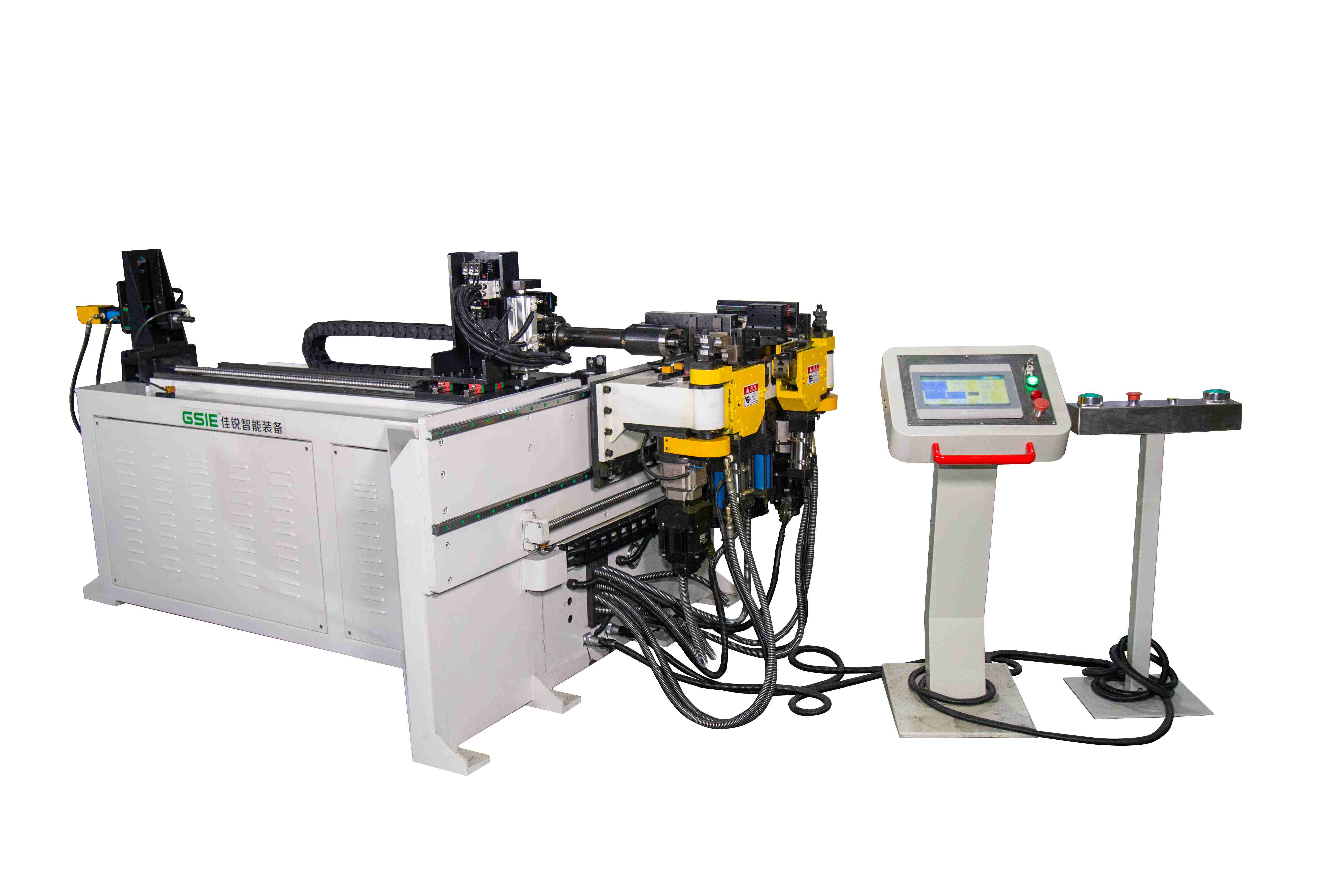

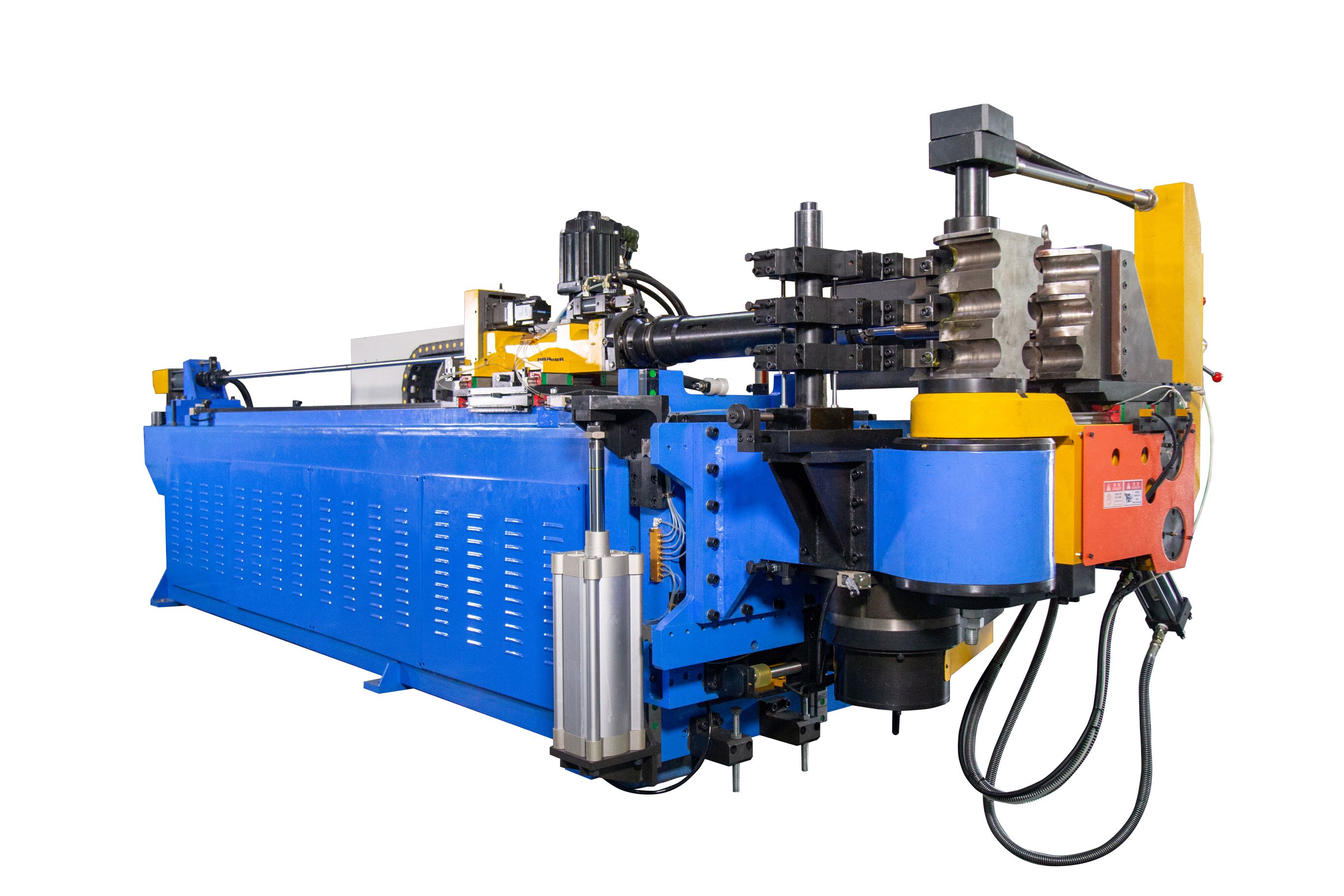

SKWRL25-R2-H

SKW-25 series CNC tube bending machine is designed for the pipe bending , especially for the pillow tube processing on car seat , bending diameter on Ø8 ~ 25, wall thickness 1.5mm for copper and aluminum tube or on Ø14mm, wall thickness 2.0mm iron tube, the clamping mechanism using hydraulic control, Y, B, C coordinate driven by servo, machine using microcomputer control. It can realize complex functions such as three-axis simultaneous movement, active and passive bending.

The machine integrates with left and right bending direction function. Two bending heads setting with parallel arrangement. Parameter setting and operation switching can be set through the Chinese or English operation interface, which is simple, convenient and reliable. With good stability, repeatability and high efficiency, it is very suitable for the bending of complex pipe fittings.